In the contemporary landscape of packaging solutions, tinplate packaging has emerged as a leading selection for food products, particularly in the world of metal food packaging. Let's dive into the diverse globe of food can lids packaging, consisting of the manufacturing procedures and developments that provide to an ever-evolving customer base. Notably, the can lid packaging solutions have to additionally align with worldwide food safety and security standards, which even more boosts the importance of utilizing top notch tinplate materials.

As the appeal of canned foods remains to climb, driven by their convenience and long service life, the need for trusted food can lids packaging has substantially raised. This need creates opportunities for business to offer and innovate custom lids that not just offer practical objectives but also improve the branding experience for makers. Custom lids can be made to include unique features, such as easy-open pull-tabs or resealable properties, catering to customer choices for comfort and simplicity of usage. The looks of can lid packaging must not be forgotten, as lively shades and engaging designs can record a customer's interest on the shelf, making the product stand out in a jampacked industry. This crossway of functionality and design is where tinplate packaging solutions succeed, supplying a canvas that can showcase brand identification while additionally serving the primary purpose of food preservation.

One of the principals in the can lid manufacturing sector is Uniteam Sourcing, which concentrates on providing high-quality packaging solutions for food makers. By understanding the vibrant nature of the food industry, Uniteam Sourcing has actually positioned itself to use tailored solutions that satisfy specific customer needs. Their knowledge in can lid packaging solutions, particularly within the metal food packaging domain name, allows them to help organizations in selecting the ideal packaging that aligns with item needs while likewise pleasing regulatory guidelines. The procedure of selecting food can lids packaging surpasses just choosing a lid; it includes considering elements such as compatibility with existing can layouts, the nature of the product being secured, and the desired life span. Integrating these factors to consider allows brands to not just maintain the quality of their foodstuff yet also attract the target group via thoughtful packaging choice.

Custom lids can be created in different sizes, forms, and setups, depending on the type of food item and the market section it aims to offer. In today's hectic world, customers are increasingly deciding for comfort, and packaging solutions that accommodate such demands are important.

As brands identify the significance of sustainable methods, the manufacturers of tinplate packaging solutions are additionally reacting by establishing environmentally friendly manufacturing techniques. Metal packaging is extensively considered as one of one of the most lasting packaging types as a result of its recyclability and the minimized carbon impact connected with its manufacturing and recycling contrasted to plastics. The food can lids packaging industry not just benefits from this lasting angle but likewise plays a critical function in promoting eco-friendly techniques across the more comprehensive food packaging industry. With growing problems about plastic air pollution, more brands are moving towards metal packaging options, which naturally sustains sustainability initiatives. This change not just resonates with mindful customers yet also allows business to connect their commitment to the setting effectively.

Collaborating with professionals such as Uniteam Sourcing can provide makers with useful insights right into the latest patterns in can lid packaging solutions. Keeping abreast of advancements in products science can lead to substantial developments in the efficiencies of food can lids.

Eye-catching and distinct graphics can be published straight onto the lids, transforming them right into a sensory experience that not just protects the food but likewise tells a tale regarding the product inside. Creative labeling on can lid packaging can connect individuals to the product, share its origins, or offer corresponding offering tips, hence boosting the total customer experience.

To underpin effective can lid manufacturing, it's crucial that businesses collaborate closely with their supplier partners, like Uniteam Sourcing, to ensure more info that the materials made use of fulfill not just useful however likewise visual objectives. By keeping open networks for interaction and click here comments, vendors can better establish solutions that adapt quickly to changing customer demands and choices. The dexterity of the production process is vital in aiding companions change swiftly to new market trends or governing criteria in food packaging.

As we dive deeper into the future of tinplate packaging solutions, one point is certain: the relevance of food can lids packaging will certainly proceed to climb. With advancements driving the sector ahead, producers can experiment with brand-new layouts, functionalities, and lasting methods that appeal to both producers and customers. As ecological awareness expands, the need for recyclable materials, such as metal lids, will certainly even more bolster the metal packaging market. Therefore, embracing a consumer-focused and lasting method in can lid manufacturing can set brands apart in a competitive landscape. As this sector develops, so also will the expectations and passions of consumers, which means that read more remaining tuned to industry patterns and technology innovations will be vital for producers looking for longevity and importance on the market.

In final thought, tinplate packaging solutions give a functional and robust system for food can lids packaging, formed by both functionality and style. The expertise from firms like Uniteam Sourcing makes certain that packaging not only straightens with current patterns however additionally anticipates future requirements. With the ongoing emphasis on sustainability and consumer interaction, the landscape of can lid manufacturing is positioned for continual growth, providing interesting possibilities for innovation that will reshape exactly how food packaging is regarded and made use of. As we look forward, the synergy between innovation, style, and liable source monitoring will define the future of food can lids packaging, reinforcing the vital function that custom lids play in the lifecycle of metal food packaging systems.

Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Kane Then & Now!

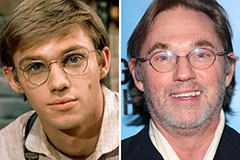

Kane Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!